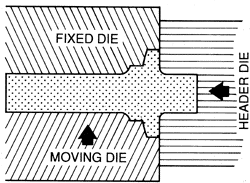

More Complex Shape of greater accuracy cannot be formed by open - die forging techniques. Commonly known as die forging or drop forging, impression - die forging makes use of cavities in special prepared dies to produce forged shapes in large quantities, the finished forged being commercially negatives or duplicates of each other.

Since the die is not fully closed, it should properly be called an impression die. The term closed-die forging, is nevertheless, often applied, while the term drop forging is sometimes used to denote forging conducted upon a hammer ; but this distinction has no particular merit.

The die cavity , however, must be filled without defects of material flow, such as could occur when the parts of the workpiece material are punched , folded down or sheared through. A complex shape cannot be filled simply by forging a round or a rectangular bar into the die cavity, and some performing steps are necessary.

The operations may be so close together that it is unnecessary to heat between them. The number of forging steps necessary to produce the finished forging in the impression die is dependent on the size and shape of the forged part, on production quantities, and on the kind of the material being forged.

Generally, when large quantities of identical forgings of greater accuracy are required as is necessary in mass production, impression - die forgings are commonly employed, and where forgings can be made by either of the several methods, the quality is comparable, and the choice is made for economic crisis.

Comments

Post a Comment