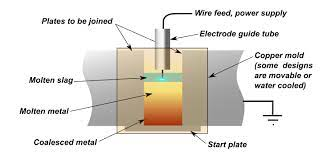

This is a welding process which produces coalescence through electrically melted flux which melts both filler metal and the surfaces of the workpiece to be melted. Welding is initiated on a starting block at the bottom of the vertically positioned joint. Flux poured around the electrode is converted to the slag that floats on a layer of molten metal confined in the joint by water cooled copper shoes (dams) that slide on the sides. The heat of the fusion is provided by resistance heating in the slag. The welding dams and head move upward as weld metal solidifies and new metal is fed in by the wire electrodes.

The consumable wire electrode may be solid or flux coated but most or all of the shielding is provided by an argon and CO2 gas mixture injected into the gap. The heat is furnished by an electrical arc between the electrode and metal pool.

Electro-slag welding is used particularly for welding thick (25mm or over) plates and structures for turbine shafts, boiler parts and heavy presses.

Comments

Post a Comment