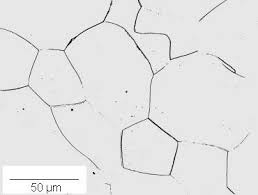

Ferrite :

It is the grain or crystal of solid solution of carbon in alpha - iron. It is relatively soft (50-100 Brinell)., Ductile and strongly magnetic.

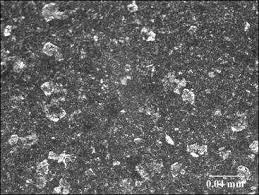

Cementite :

Cementite is a chemical compound of 93.33 per cent iron and 6.67 per cent carbon. It is identified as round particles in the structure. Being extremely hard ( about 1400 Brinell ) and Brittle. It has no ductility. Cementite becomes ferro - magnetic below 210*C.

Pearlite :

It is readily recognized by its pearly lustrous appearance and its structure of thin alternating plates of 13 per cent cementite in a matrix of 87 per cent ferrite. Pearlite is a strong metal having 180 Brinell.

Austenite :

It is a solid solution of carbon in gamma-iron. It is generally soft and ductile than ferrite, but denser than ferrite , and is non- magnetic.

Sorbite :

It is a finely dispersed pearlite, and the properties are intermediate between those of pearlite and troostite. The Brinell Hardness is 350.

Troostite or Bainite :

It is the most finer acicular (needle-like) structure of austenite decomposition; and is composed of two equilibrium phases of ferrite and cementite.

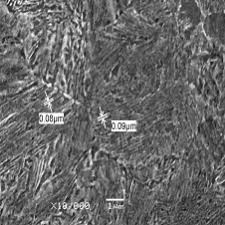

Martensite :

Martensite is obtained by decomposition of austenite when it is very rapidly cooled. It is cooled of needle-like crystals in angular arrangements. Martensite is very hard (650-750 Brinell), brittle, and magnetic.

Comments

Post a Comment