a) Summer Air - Conditioning For Hot and Wet Weather :

When the air is hot and wet, the treating of the air in air - conditioning system differs from other methods. Because air contains more quantity of water vapour than the required quantity. So, the air conditioning system has to remove the water vapour by dehumidifying.

During hot weather, air is first passed through air filter to remove the dust and then it is passed through the cooling coil to remove water vapor. At that time, the temperature of air becomes below its dew - temperature due to reduction in surface temperature of cooling coil. This surface temperature of coil is controlled by varying the quantity of coolant.

During wet weather, the air coming out from the cooling coil is passed over the heating coil to heat up to the required temperature. Then the heated air is directly supplied to air conditioned space. The amount of air passed through air conditioned system is controlled with the help of air dampers according to the load in air conditioned space.

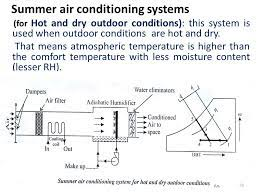

b) Summer Air - Conditioning For Hot and dry weather:

During hot weather, air at low relative humidity is first passed through air filter to remove the dust and then it is passed through the cooling coil to remove water vapor. At that time, The temperature of air becomes below its dew-temperature due to reduction in surface temperature of cooling coil. This surface temperature of coil is controlled by varying the quantity of coolant. Then the air is passed through spray type humidifier to increase humidity and its is passed through eliminator to remove water droplets. The quantity of passed through the air conditioned space varies with the load calculations.

Comments

Post a Comment