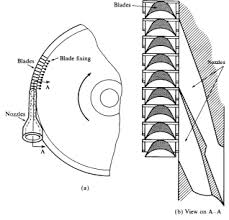

It consists of one set of nozzle followed by one set of moving blades. A rotor is mounted on a shaft. The moving blades are Attached to the rotor.

The steam from the boiler at high pressure and low velocity enters the nozzle which is fitted in the casing. The steam expands in the nozzle where the pressure drops to p1 and velocity increases to V1. This high velocity steam jet impinges over the blades mounted on the rotor attached to the shaft. This causes the rotation of the turbine shaft and thus useful work is obtained. It is noted that the pressure of the steam when it moves over the blade remains constant but the velocity decreases.

The upper portion shows the longitudinal section of the upper half of the turbine. The middle portion shows the development of the nozzles and blading. The bottom portion shows the variation of velocity and pressure of the steam during which it passes through nozzles and blades.

DISADVANTAGES OF SIMPLE IMPULSE TURBINE :

* Since all the kinetic energy of the high velocity steam has to be absorbed in only one ring of moving blades, so the velocity of the turbine is too high i.e, up to 30000 rpm for practical purposes. Such high rotational speeds can only be utilized to drive generators with only large reduction gearing arrangements.

* The Velocity of Steam at exit is sufficiently high thereby resulting in a kinetic energy loss called "Carry over loss " or " leading velocity loss ". This loss is so high.

Comments

Post a Comment